Equipment

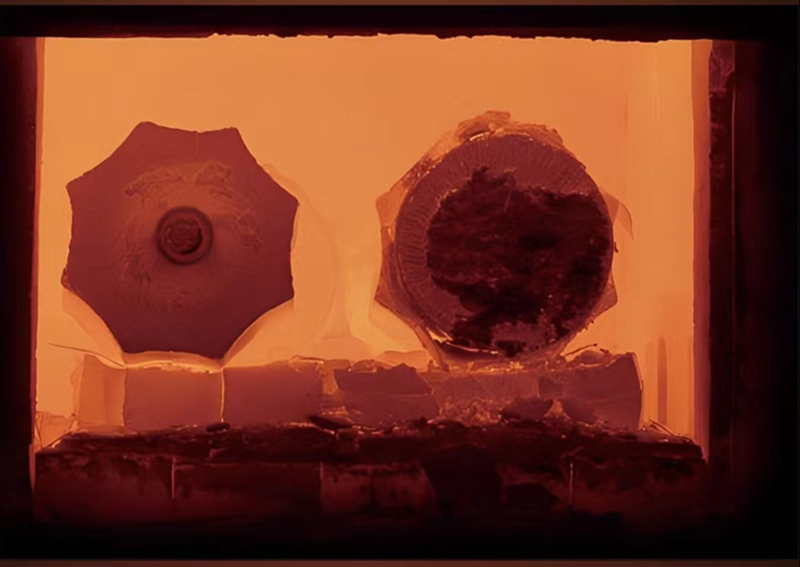

Electroslag Equipment

5 tons, 8 tons, 10 tons gaselectroslag remelting furnace, according to different customer needs to produce a variety of materials less than 10 tons of electroslag ingots and die steel forgings.

Product process

perature diffusion of electroslag ingot → isothermal forging → ultrafine particle treatment → isothermal spheroidization and return treatment.

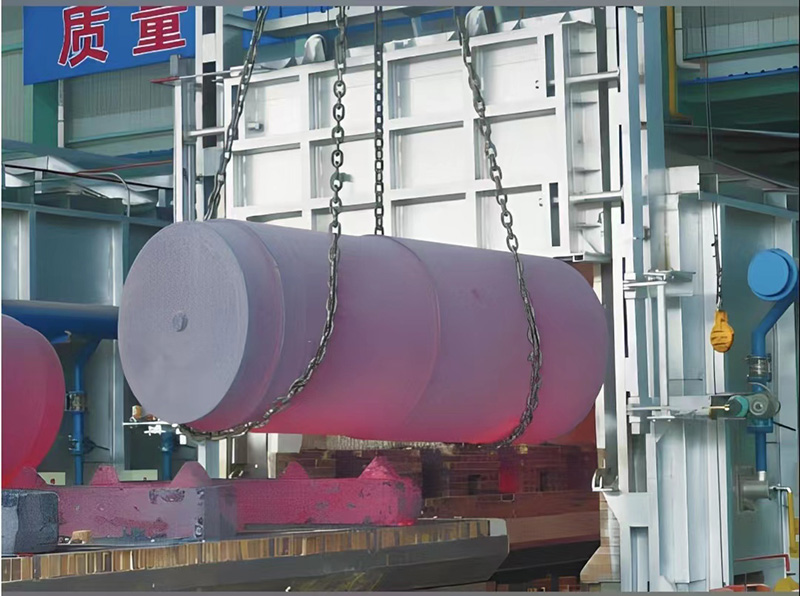

Forging Equipment

Our company has a domestic leading level of 4500t, 1600t hydraulic press, supporting 50t, 15t hydraulic forging operation machine, equipped with natural gas regenerative heating furnace 4 sets, forging heat treatment furnace 4 sets, all using automatic ignition, automatic regulation, automatic temperature control; With 5t, 3t electro-hydraulic hammer, 2t splint hammer, 1t air hammer, equipped with operating machine, loading and taking machine, all realize mechanization, can produce forging single weight tonnage 50kg - 50t.

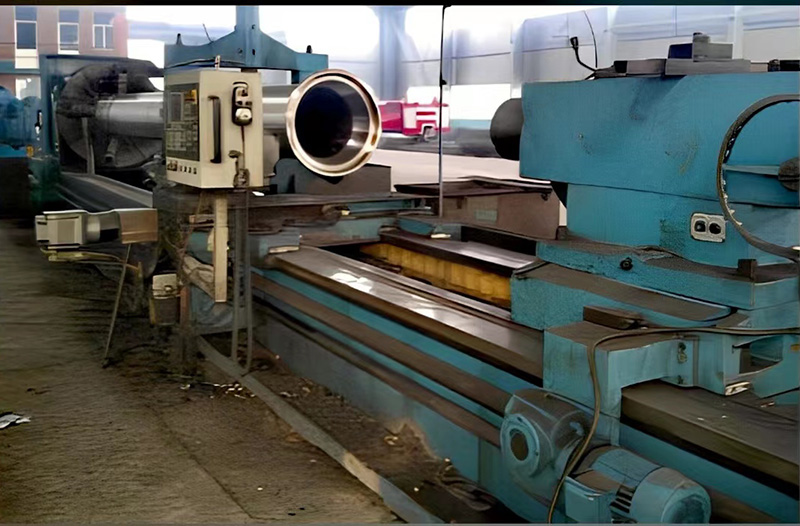

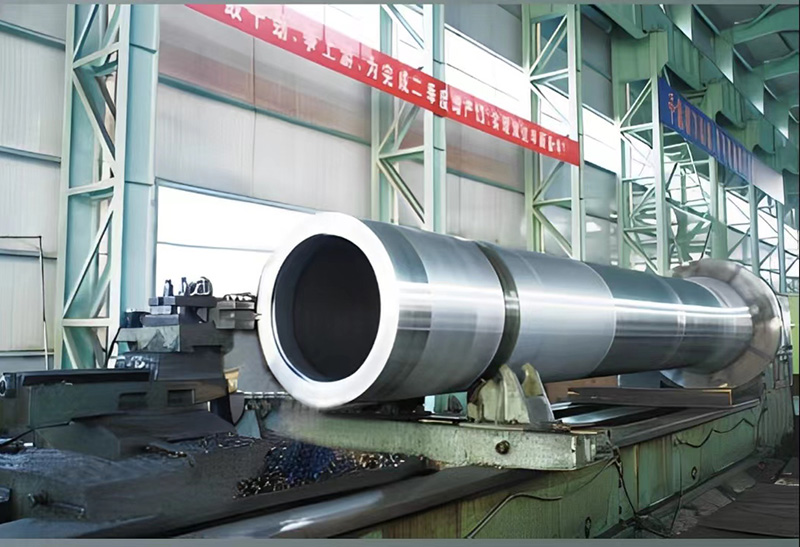

Machining Equipment

Our company has more than 40 sets of heavy machinery processing equipment, which can be used for turning, milling, drilling and other processes diameter 2m, length 16m, weight 50t; Gantry planer 1, can process 2mx6m workpieces; 6 deep hole processing machines, can process Φ35-Φ1400 aperture and processing a variety of hollow parts.

Quenching and Tempering Equipment

The main production equipment is: 1 φ2.2x12m well type heat treatment furnace, 1 8x3x3m trolley type resistance furnace, 1 4x2x2m table type resistance furnace, 1 8x3x3m gas type trolley type furnace, 1 6x3x2m gas type trolley type furnace, 1 7.5x4x2.5m table type gas heat treatment furnace, The double-layer intercrossing quenching crane has one 50/10T and 32/5t respectively, which can carry out the heat treatment process of normalizing, tempering, tempering and tempering for the cast, forging and parts of various materials under 50 tons.

Relying on the advantages of the testing center of the company, the heat treatment production line carries out the tissue analysis and depth testing of various heat treatments (Buloh, Loh, Wei hardness testing, ultrasonic flaw testing).

Deep Hole Equipment

Has all kinds of large, medium and small deep hole boring machine, and the supporting CNC equipment, can process each class large shaft class and deep hole products. The matching sleeve and drilling tools are complete, which can be processed with a maximum length of 15000mm, a maximum outer diameter of 1800mm, and an inner diameter 80-1500mm, tube mold can process DN80-DN1400 range of various specifications of products; 2000mm, 1600mm, and 1250mm lathes equipped with Siemens numerical control system, good stability, wide processing range, high precision.

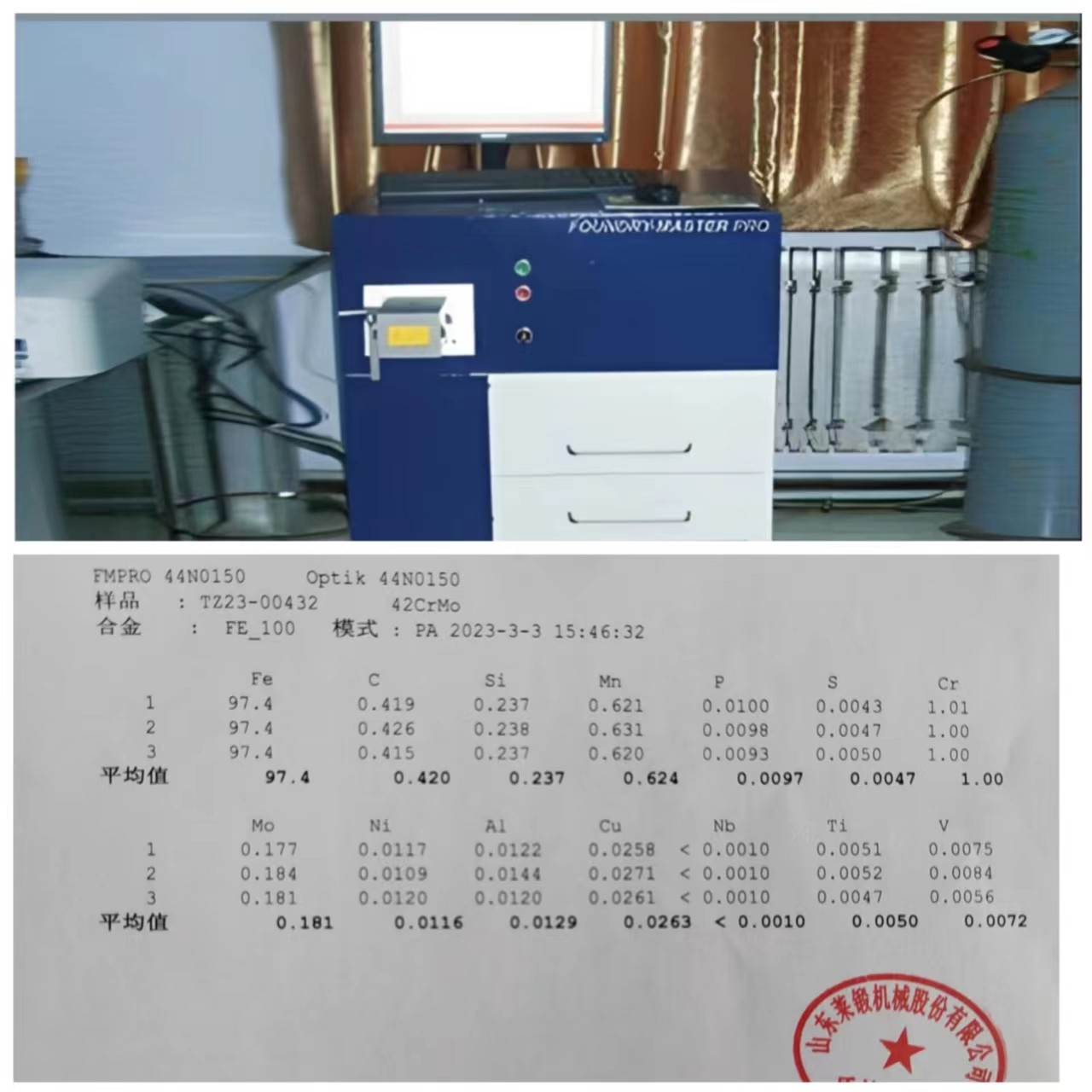

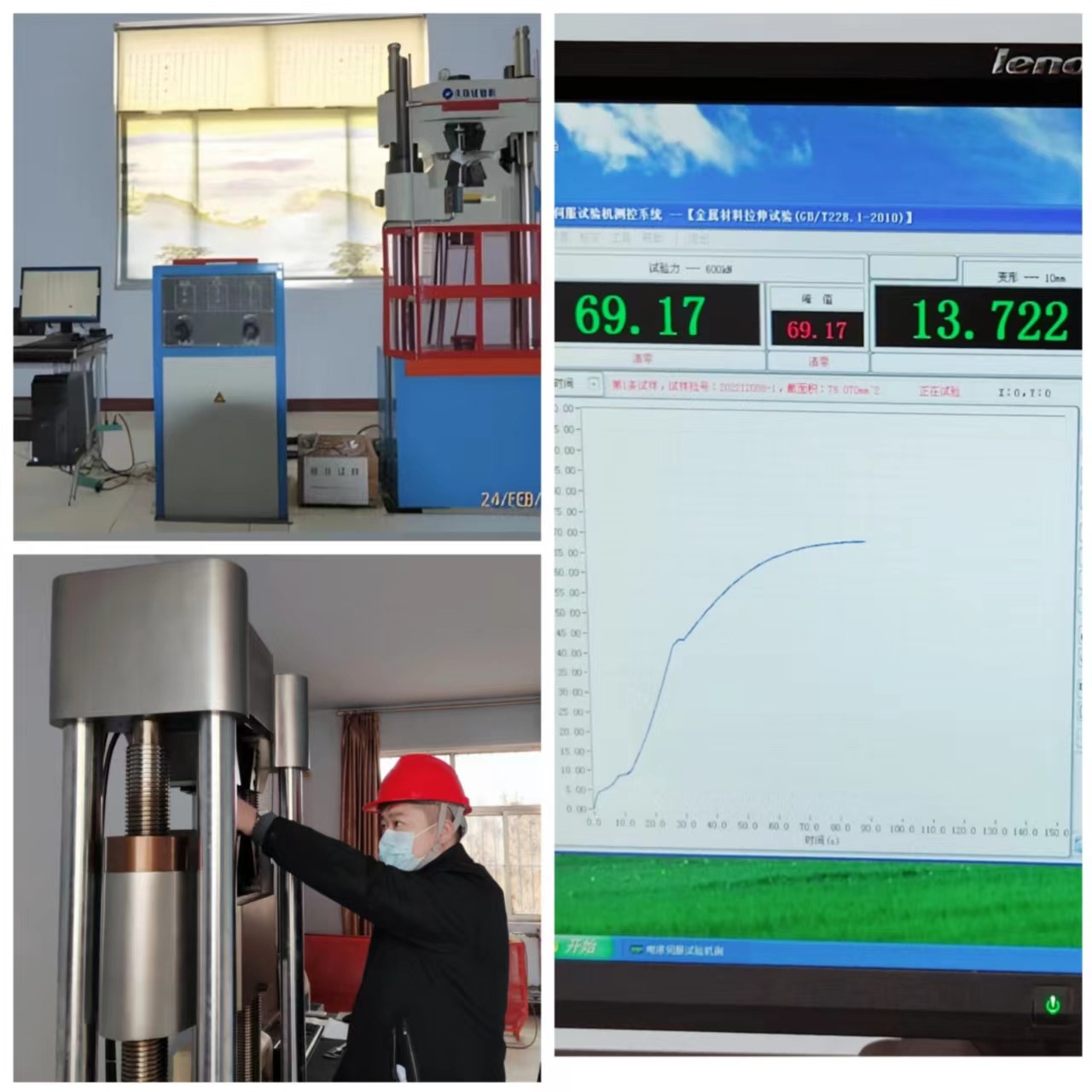

Testing Equipment

Our company is equipped with various specifications of the flaw detector, mechanical performance testing machine, metallographic microscope, spectrometer, all kinds of hardness tester, high-precision measuring tools and other inspection test equipment, and maintain a cooperative relationship with domestic and foreign third party testing institutions, according to customer requirements of the third party testing, to ensure that the factory products 100% .